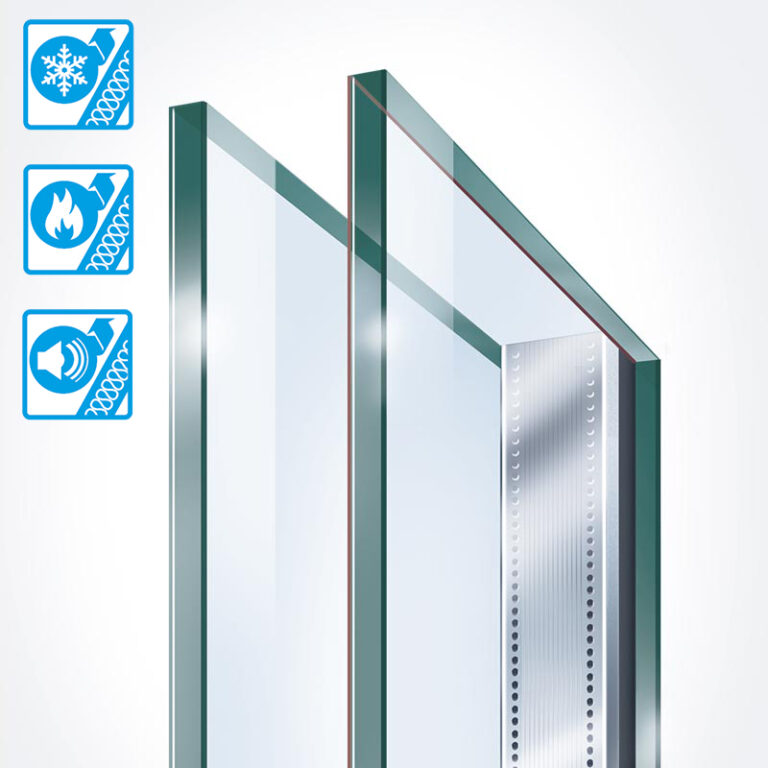

Thermal-insulated Glass

The foundation of every window or glass façade panel is thermo-insulated glass. These are produced in two sets: double or triple glass sets.

Materials used in the production process, as well as the process itself are certified and approved by CEKAL which guarantees the highest quality possible.

Thermo-insulated glass can be used for:

– Thermal insulation

– Sound insulation

– Anti-vandal protection

– Bullet-proof protection (ballistic-resistant glass)

– Protection of the non-controlled breaks

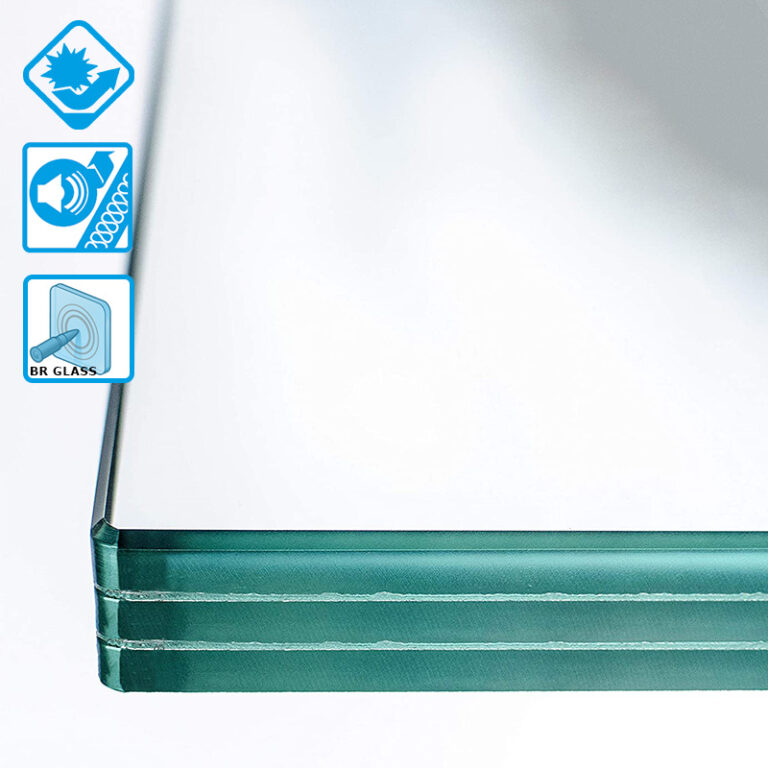

Laminated glass (VSG) is built from two or more glass panels connected with PVB (polyvinyl butyral) foil which are highly resistible to tearing. Foils can be colored or colorless, with high UV and sound protection. Glass layers can have thes same or different thicknesses.

Laminated glass doesn’t disperse into small pieces when broken because it’s protected with the foil,. This type of glass is the first choise when it comes to commercial buildings where ballistic security is required or for glass interior constructions such as glass walls and glass staircases.

The main characteristics of tempered glass are durability, firmness and good thermo-resistance.

The glass tempering process is basically heating of the glass (up to 600 degrees) and the fast air-cooling of it, which helps the glass to reach all the above-mentioned characteristics.

When broken this glass turns into small, non-sharp pieces that are not harmful at all.

Tempered glass is the right choice for you if you are looking for high mechanical and thermal firmness.

Tempered glass is used for:

– Glass facades (roof)

– Fences

– Interior elements

– Fixed or movable glass panels on boats

– Glass treads

– Cooling devices

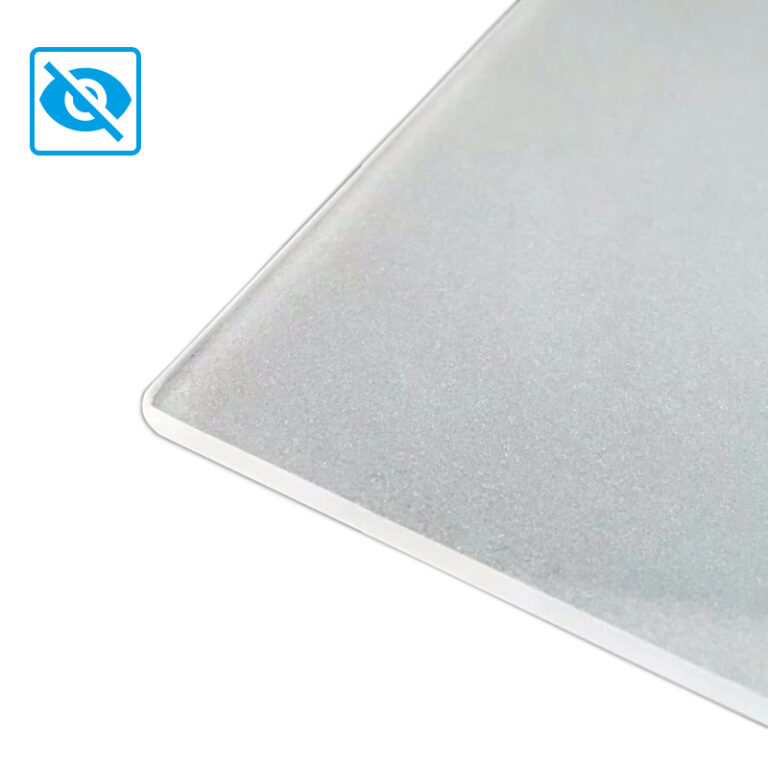

When you spray the sand across the glass surface using high air pressure, the glass gets micro scratches that give it a satin look. So the transparent glass surface turns into a blurred glass.

When combined with different PVC templates, sanded glass offers a lot of design options. Sanded glass is mostly used for interior walls and balcony fences.

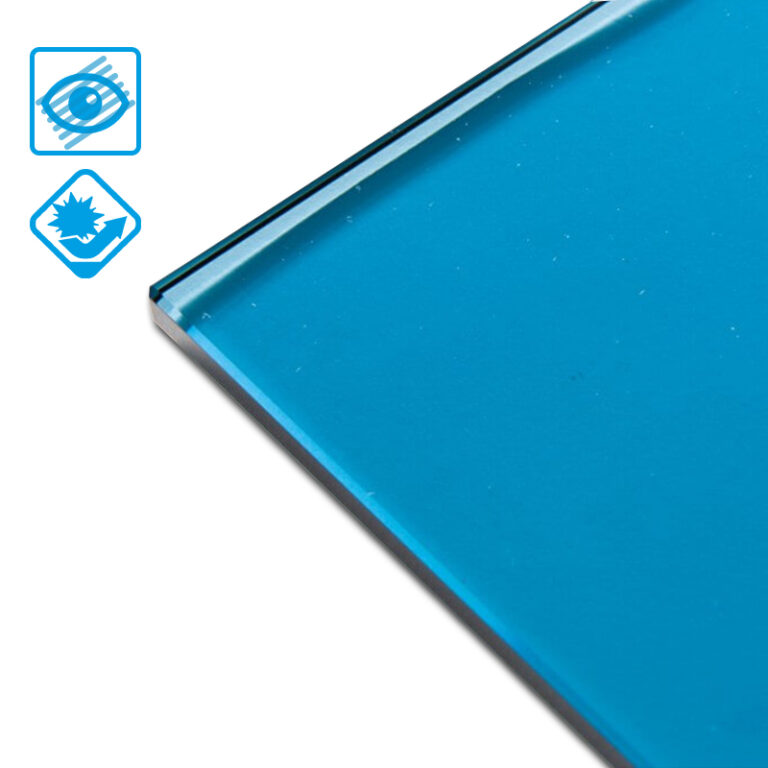

Enamelled glass is produced in different sizes from: 4 up to 24 mm (thickness).

The production process is simple: we apply enamel varnish (any color from the RAL spectrum of colors), which is later heated at 650 degrees.

This glass is used for parapet fields on glass facades, as well for interior designs and decorative constructions in machinery.

We provide services such as CNC glass processing, polishing, and edge finishing. All according to your wishes and specifications.

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.