SAVABIEN company is processing all types of (single) glass and produce all kinds of thermal-insulated glass (two layers, three layers). We use all types of aluminum molds that are produced on automatic bending machines (aluminum or PVC molds with improved thermal characteristics – “warm edge”).

We also produce all types of façade glass, and we are proud owners of the Dow Corning certificate.

At Savabien, we also produce ballistic glass which is highly protective, as well as glass that is covered with anti-vandal foil (good for shop windows). Professionals tested this type of glass, and the result is: To break this glass, you will need to punch it 70 times with a medium-size saw.

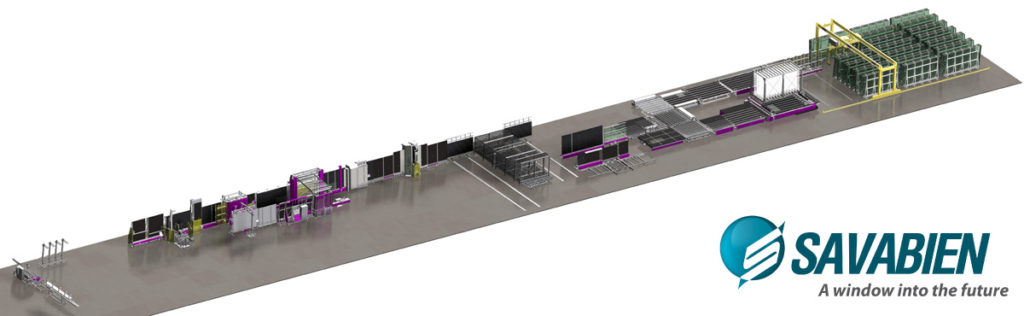

This production facility is the proud owner and user of the latest Lisec machinery.

4mm low emission glass (film foil on position 2) + 15mm aluminium mold Argon 90% + 4mm standard float glass + 15mm aluminium mold Argon 90% + 4mm low emission (film foil on position 5). This thermal package has thermal conductivity Ug=0.6w/m2K.

Our standard product is combination of: 4mm standard float glass+16mm aluminium mold Argon 90% + 4mm low emission glass. This thermal package has thermal conductivity Ug=1.1 W/m2K

Necessary cookies are absolutely essential for the website to function properly. This category only includes cookies that ensures basic functionalities and security features of the website. These cookies do not store any personal information.

Any cookies that may not be particularly necessary for the website to function and is used specifically to collect user personal data via analytics, ads, other embedded contents are termed as non-necessary cookies. It is mandatory to procure user consent prior to running these cookies on your website.